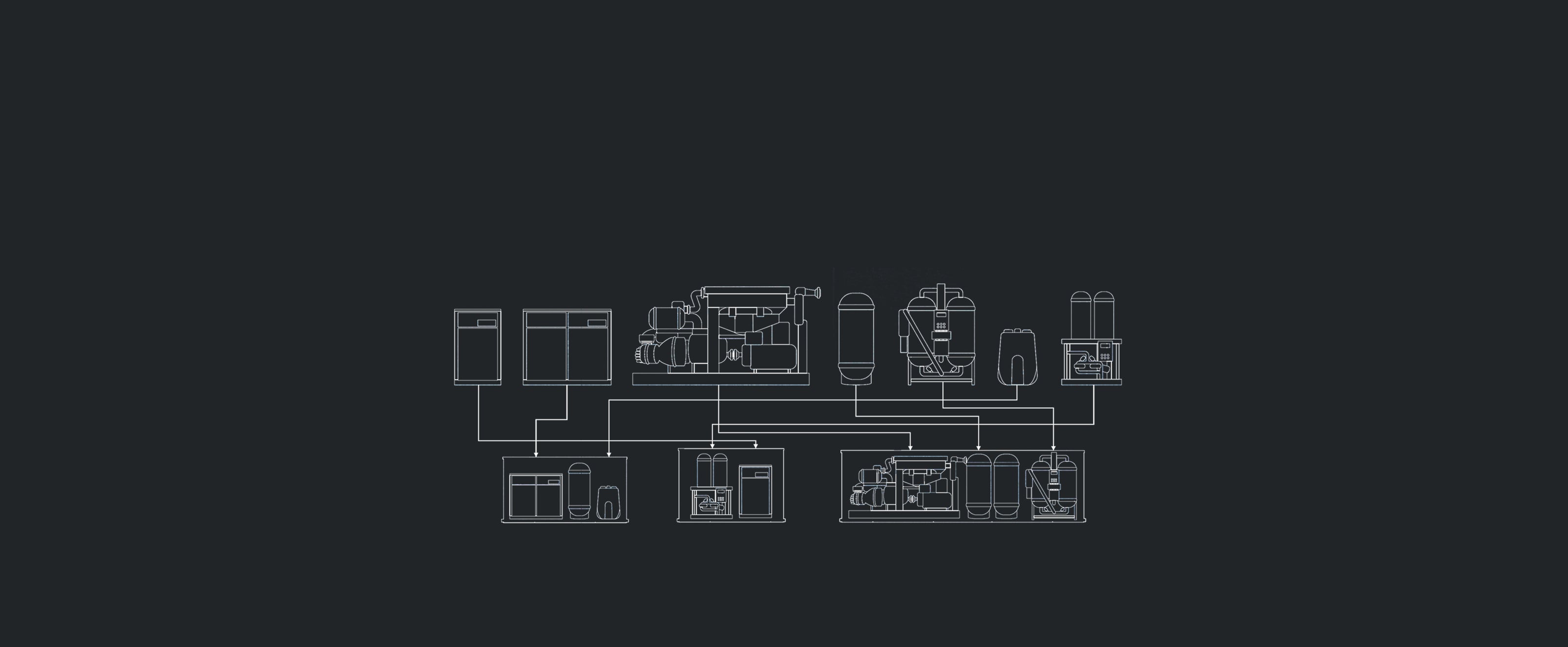

Wether you require one or multiple compressors, wet and dry tank(s), air dryer(s),

oil & water separator, or even a nitrogen generator system,

we build from ground to top your custom solution.

Electrical

The Nerve Center of a Compressed Air Enclosure

- Power Distribution: Keeps motors, fans, dryers, and controls running smoothly.

- Automation & Control: PLCs manage cycles, monitor performance, and trigger alarms when needed.

- Safety Features: Includes overload protection, grounding, surge suppression, and emergency shutoffs.

- Monitoring: Sensors and displays provide real-time diagnostics and support predictive maintenance.

- Durability: Housed in NEMA 4 rated enclosures to resist dust, moisture, and heat.

Piping

The circulating system of a Compressed Air Enclosure

- Maintains Pressure: Prevents drops that waste energy and reduce performance.

- Controls Moisture: Sloped lines and drains remove water and contaminants.

- Prevents Leaks: Quality materials and fewer joints cut energy loss and maintenance.

- Improves Safety: Reduces vibration, corrosion, and failure risks.

- Allows Growth: Designed for easy expansion and reconfiguration.

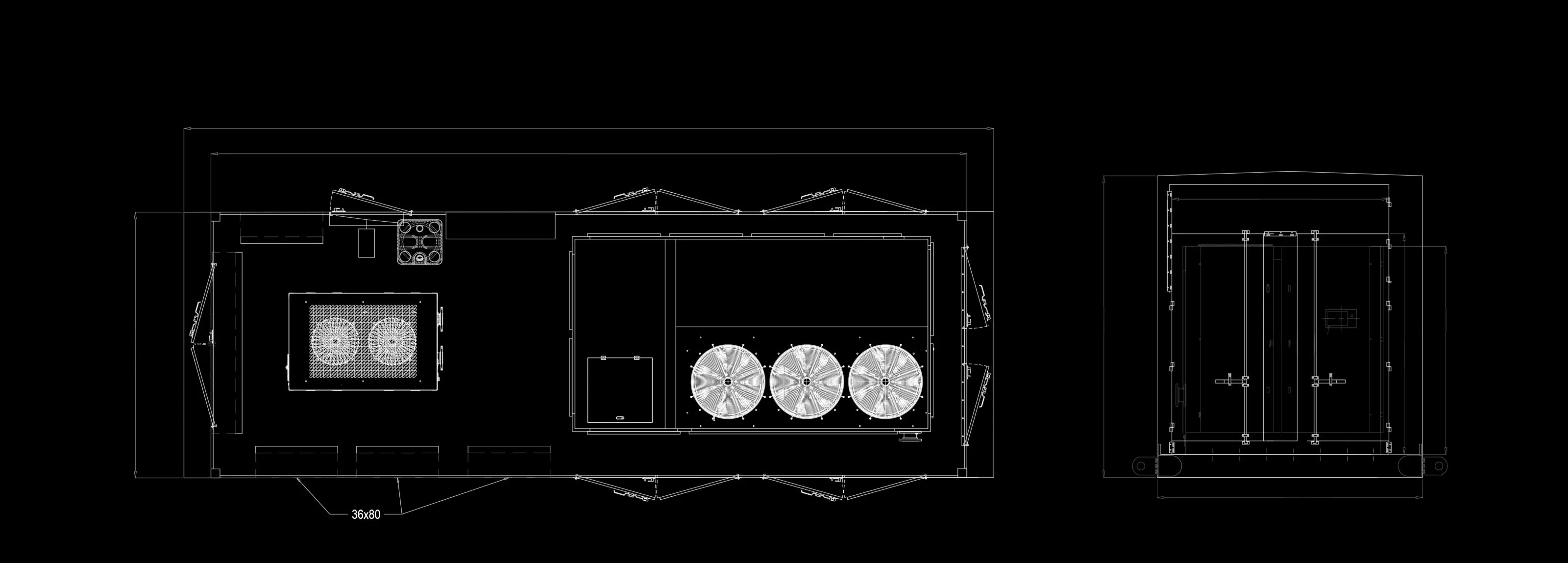

Ventilation

Essential to keep compressors cool, efficient, and reliable.

- Prevents Overheating: Maintains performance and prevents damage.

- Boosts Efficiency: Cooler air reduces energy use and costs.

- Extends Equipment Life: Protects seals, motors, and electronics from heat stress.

- Improves Safety: Prevents buildup of fumes, vapors, and fire risks.

- Controls Noise: Helps manage heat and sound for a safer workspace.

Good airflow means better performance, lower costs, and longer system life.